- HOME

- Technology

- Process

Purchasing Order

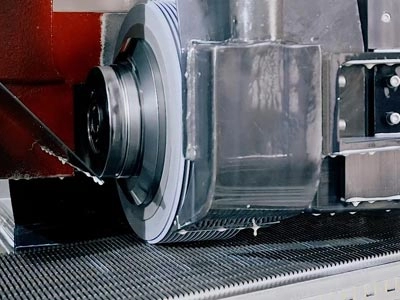

KAI HE is exporting racks and pinions to countries all over the world, such as Europe, America, Northeast Asia. At present, there are more than 15 overseas agents selling our products.

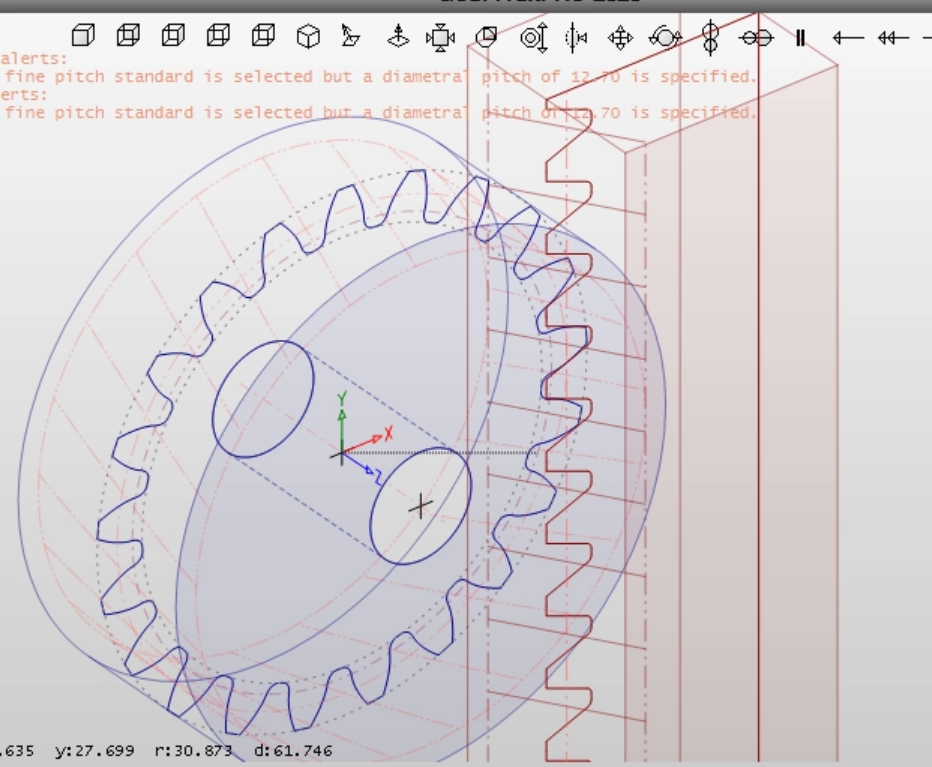

RпјҶD

To make sure have good motion when rack and pinion move mutually, KAI HE's engineer doesn't miss any details of gear data calculation. We can provide any Rack and Pinion drawings in 2D or 3D file, not only standard product but also customized product. Tell us your needs!

Raw Material

The materials used by KAI HE are all made in Taiwan. We have ensured that the materials what we using can keep good mechanical performance.

Surface Milling

To get required size of rack the first step is rack surface milling.

Chemfer

In order to let users to install our racks better, we will do a chamfering action on the rack mounting surface.

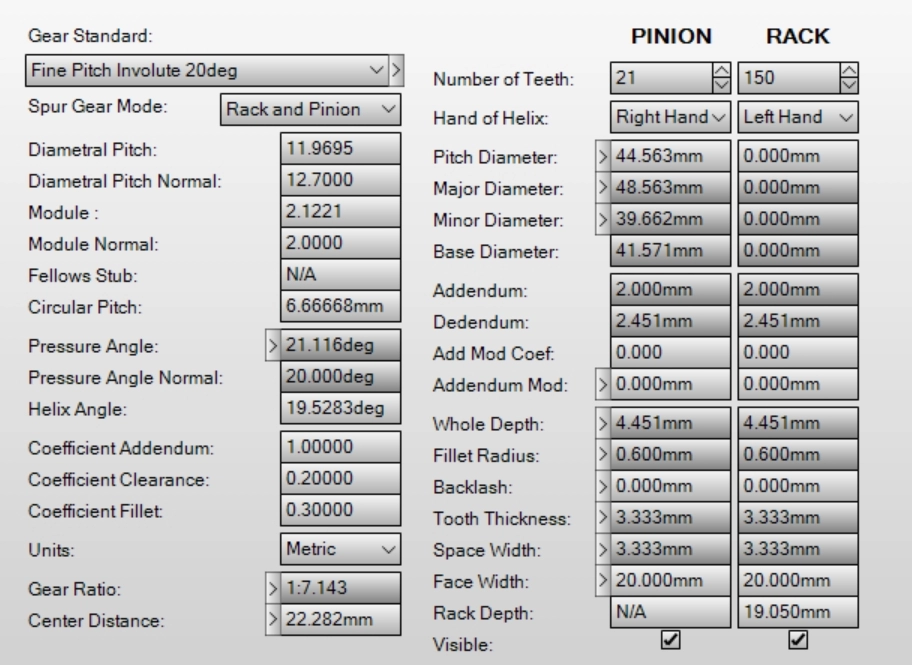

Teeth Milling

KAI HE produces high quality racks with German rack cutting machine, We produce rack with working length : 2200 mm and up to Module 12.

Heat-Treatment

KAI HE has mature experience in induction hardening treatment of racks. After teeth induction hardening that can have a longer machinery life.

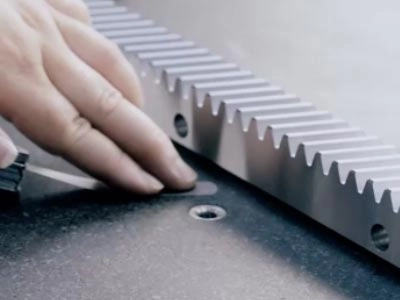

Bending Balance

KH's racks are balanced by hand after heat treatment. In order to make sure that no any torsion , wavy , twisted , crooked in rack. So you will find out that how is a straight rack is it when you install on the base.

Mounting Hole Drilling

KAI HE drills the mounting holes for each rack. Of course, we can also make special mounting holes according to the needs of customers.

Surface Grinding

Before teeth surface grinding of each rack, KAI HE will first grind each of side surfaces on racks. This is to ensure that the rack can achieve better accuracy and reduce errors during installation.

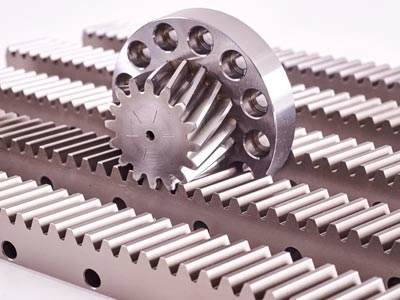

Teeth Surface Grinding

To make sure have performance as below points. KAI HE always focuses on the quality in teeth grinding process after teeth hardening.

- Higher acceleration and speed

- Less noise

- Longer life of the system

- Higher force impressed on the tooth side

- High precision

- Lower energy consumption

Laser Mark

After the rack production is completed, we will laser mark KH's LOGO and production number. Of course, every rack produced by KAI HE has each production number. In addition to KAI HE brand, we also do OEM with famous manufacturers in the world.

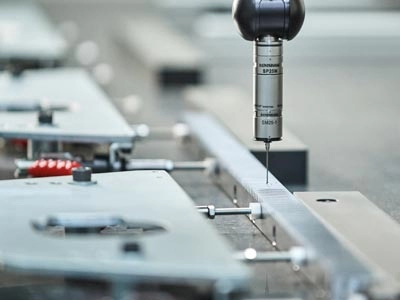

QC Measuring

Each rack produced by KAI HE has undergone rigorous quality inspection. We using German coordinate measuring machine and Japanese measuring tools to measure the quality of each racks.

Package & Shipment

KAI HE packs each rack after anti-rust treatment, pack it in a smoked wooden box, and export it to countries all over the world.